SLANT BED CNC LATHE

SLANT BED CNC LATHE

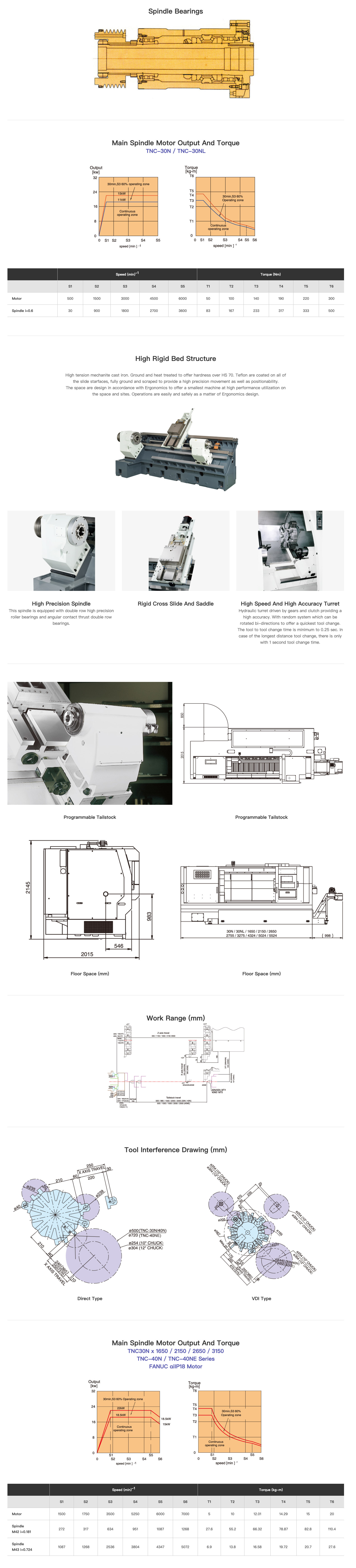

TNC-40N / 40NL

- High rigidity and heavy cutting.

- 45 degree slant bed structure are easily for chip removals.

- Easy operation.

- Enclosed electrical cabinet.

- To assure high accuracy machining & machine life, spindle bearing hiusing with high precision grinding machining complete spindle with pulleys dynamic balance test.

- Programmable tailstock.

- Separated coolant tank.

MENU

| Capacity | |

|---|---|

| Swing over Bed | Ø 640 mm (25.2”) |

| Swing over cross slide | Ø 430 mm (16.9”) |

| Distance between centers | 670 / 1150 mm (26.4” / 45.3”) |

| Cutting diameter | Ø 480 mm (18.9”) Direct / Ø 440 mm (17.3”) VDI |

| Hydraulic chuck | Ø 304 mm (12”) / OPT Ø 380 mm (15”) |

| Bar capacity | Ø 90 mm (3.5”) |

| Bed width | 480 mm (18.9”) |

| Bed slant angle | 45 degree |

| Spindle | |

| Spindle nose | A2-8 |

| Spindle hole | Ø 102 mm (4”) |

| Spindle taper | 1/20 |

| Spindle speeds | 10 ~ 2500 R.P.M |

| Spindle motor | FANUC αil 18 (18.5 / 22 kw) + 2 steps gear box (1:4) |

| Spindle dia. (OD) | Ø 160 mm (6.3”) |

| Turret | |

| Turret type | Hydraulic turret / Servo turret (OPT) |

| Tool station & size (OD) | 10 / 12 (OPT), 25 x 25 mm (1” x 1”) |

| X travel | 255 mm (10”) |

| Z travel | 650 / 1150 mm (25.5” / 45.2”) |

| Y travel | +- 60 mm |

| Rapid traverse | X: 18 M / MinZ: 18 M / Min |

| ID Tool holder dia. | Ø 40 mm (1.6”) |

| Tailstock | |

| Tailstock travel | 550 / 1050 mm (21.6” / 41.3”) |

| Quill diameter | Ø 110 mm (4.3”) / OPT Ø 160 mm (6.3”) |

| Quill travel | 100 mm (3.9”) |

| Quill taper | MT4 (OPT MT5) |

※ The specifications are subject to change without prior notice.

Features

High rigidity and heavy cutting

45 degree slant bed structure are easily for chip removals

Easy operation

Enclosed electrical cabinet

To assure high accuracy machining & machine life

Spindle bearing housing with high precision grinding machining

Complete spindle with pulleys dynamic balance test

Programmable tailstock

Separated coolant tank

45 degree slant bed structure are easily for chip removals

Easy operation

Enclosed electrical cabinet

To assure high accuracy machining & machine life

Spindle bearing housing with high precision grinding machining

Complete spindle with pulleys dynamic balance test

Programmable tailstock

Separated coolant tank

This site uses cookies to improve your browsing experience. we'll assume you're OK to continue. If you want to read more about this, please chick PRIVACY thank you.

Confirm