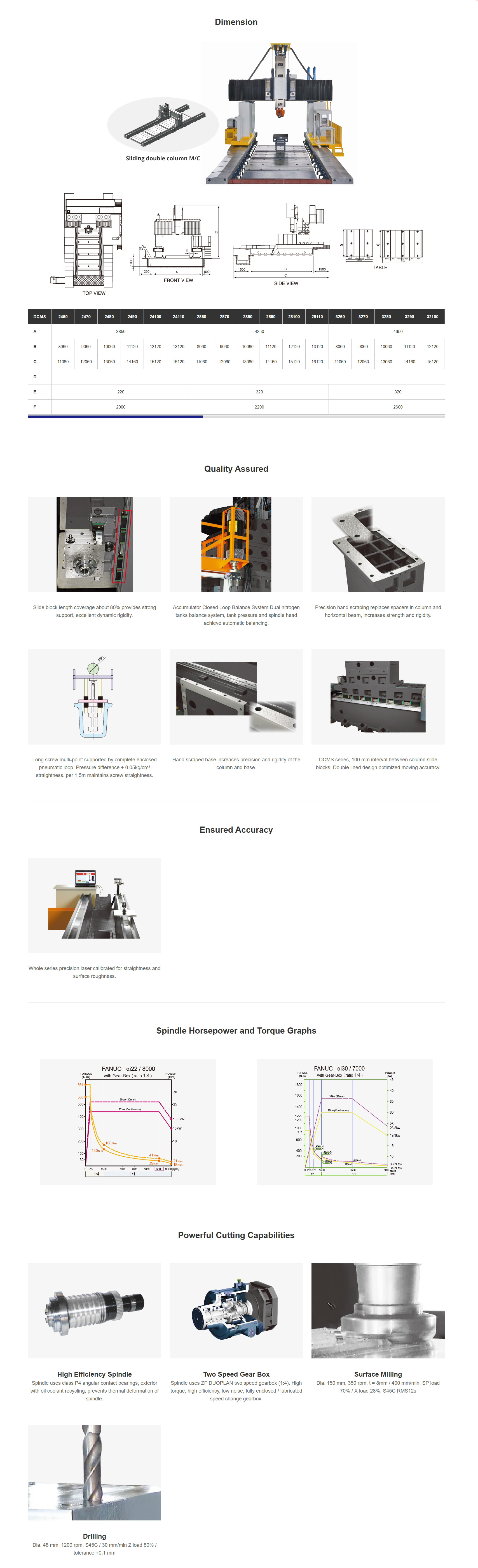

DOUBLE COLUMN MACHINING CENTER

DOUBLE COLUMN MACHINING CENTER

DCMS-24

- Excellent structural rigidity

- Optimized spindle box

- Optimized Z axis balance system

- Optimized feeding system

- Optimized feed structure system

- Powerful spindle, high cutting capabilities

MENU

| Table | |

|---|---|

| T-Slot (W x D x M) | 28 mm x 500 mm |

| Length | From 6000 mm to 36000 mm, in step of 1000 mm(From 236” to 1417”, in step of 39.4”) |

| Width | 1600 mm(63”) |

| Maximum load | 3000 kg/m2 |

| Travel | |

| Longitudinal travel(X axis) | From 6000 mm to 36000 mm, in step of 1000 mm(From 236” to 1417”, in step of 39.4”) |

| Cross travel (Y axis) | 2400 mm(94.5”) |

| Vertical travel (Z axis) | 1100 mm / 1400 mm (opt) |

| Distance from spindle end to table | 1080-2180 mm / 1020-2420 mm (opt) |

| Distance from spindle center to column | 427 mm (16.8”) |

| Distance between columns | 2450 mm(96.5”) |

| Spindle | |

| Spindle taper | BT50 |

| Spindle drive motor(Con./ 30min) | 22 / 26 kw (opt 30 / 37 kw) |

| Spindle speeds | 6000 rpm |

| ATC | |

| Tool size | Dia. 125 mm (4.9”) |

| Max. tool size | Dia. 220 mm (8.6”) |

| Tool storage capacity | 32 tools |

| Max. tool length | 400 mm |

| Max. tool weight | 20 kgs |

| Tool shank & pull stud | BT 50 45˚ |

| Feed | |

| Cutting federate | 6000 mm/min |

| Rapid traverse (X/Y/Z) | 12 / 12 / 10 |

| Miscellaneous | |

| Power requirement | 70 KVA / 80 KVA (with 30 kw / 37 kw spindle motor) (opt.) |

| Pneumatic requirement | 6.5 kgs / cm² |

| Machine size length | From 13500 mm to 43500 mm, in step of 1000 mm |

| Machine size width | 6500 mm(255.9”) |

| Machine size height | 6500 mm |

| Machine weight | 50 up ton |

※ The specifications are subject to change without prior notice.

Features

Capable of heavy cutting and high-speed machining

Excellent for precision machining for extra heavy parts

Built with high quality Meehanite cast iron and ductile iron

Roller type linear guide ways on X, Y, Z axis

Direct drive high speed spindle combines with a high/low speed gear box

Accumulator type automatic compensation balancing system on headstock

Excellent for precision machining for extra heavy parts

Built with high quality Meehanite cast iron and ductile iron

Roller type linear guide ways on X, Y, Z axis

Direct drive high speed spindle combines with a high/low speed gear box

Accumulator type automatic compensation balancing system on headstock

This site uses cookies to improve your browsing experience. we'll assume you're OK to continue. If you want to read more about this, please chick PRIVACY thank you.

Confirm